The Anatomy of A Lift Station: A Beginner’s Guide to How Factory-Built Lift Stations Move Wastewater in Sunrise Beach, MO

Wastewater infrastructure plays a vital role in maintaining public health and environmental sustainability. In communities like Sunrise Beach, MO, where varying elevations and population distributions make gravity-fed systems impractical in certain areas, waterwaste lift stations serve as essential components in the collection and transfer of sewage. These factory-built systems are carefully engineered to pump wastewater from lower elevations to higher elevations, allowing it to continue its journey to treatment facilities. For homeowners, business owners, and local municipal leaders looking to understand this hidden but essential technology, learning about the anatomy and function of lift stations offers valuable insight into how modern sanitation systems function.

What a Lift Station Is

A lift station, also known as a pump station, is an integral part of wastewater management systems designed to move sewage or stormwater from lower to higher ground. In regions like Sunrise Beach, MO, where natural topography doesn’t always permit gravity-driven flow, waterwaste lift stations become a necessity. These systems are especially critical in waterfront and hilly areas where sewer lines can’t be installed with enough downward slope to carry wastewater to a treatment plant.

Factory-built lift stations are prefabricated units that come complete with all necessary components, reducing the need for complex on-site construction. These compact and efficient systems are engineered to function reliably over long periods, even under harsh environmental conditions. By understanding their purpose, it becomes clear why they are indispensable to the sanitary infrastructure of communities across Missouri.

The Core Components of a Waterwaste Lift Station

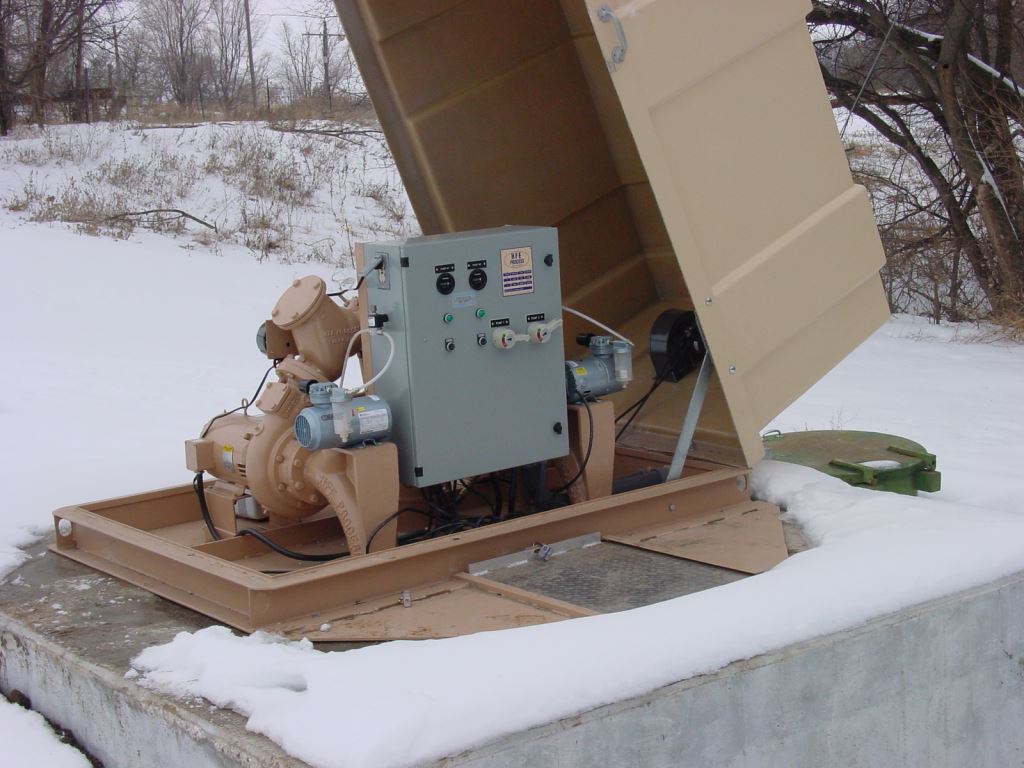

Each lift station is composed of several key components, each playing a critical role in its operation. The wet well, which serves as the holding chamber for incoming wastewater, is typically located underground. As sewage flows into this chamber, it accumulates until it reaches a predetermined level, at which point a control system activates the pumps.

Pumps are the heart of any lift station. Submersible pumps are most common in modern systems due to their efficiency and low maintenance requirements. These pumps push the wastewater through pressurized discharge pipes, known as force mains, toward higher elevation gravity sewer lines or directly to a treatment plant.

The control panel is another vital element. It includes sensors, float switches, or transducers that monitor the wet well’s wastewater level. Once a certain level is reached, the control system activates the pumps. In some setups, a backup power source such as a generator ensures that the system continues functioning during power outages, which is especially important during storms or flooding.

Ventilation, alarms, and access hatches are additional features that contribute to the safety and operability of the station. Each element works in coordination with others to ensure the seamless movement of wastewater, making modern lift stations not just efficient, but also highly reliable.

How Lift Stations Operate in Real Time

In everyday operation, the process begins as household or commercial wastewater flows by gravity into the wet well. As the waterwaste level rises, the control system constantly monitors its height. Once the wastewater reaches a specified trigger point, the pumps engage automatically. The wastewater is then pressurized and pushed up through the force main and onward to a gravity-fed sewer line or a treatment facility.

This cycle repeats as wastewater accumulates. Advanced lift stations are designed with redundancies, such as alternating pumps to balance wear and tear or having multiple pumps to handle variable flow rates. This feature is crucial in areas like Sunrise Beach, where seasonal population changes can dramatically affect water usage and wastewater volume.

Monitoring systems allow operators to receive alerts if something goes wrong. For example, if the pumps fail or the water level gets too high, an alarm will notify technicians, prompting a quick response to prevent overflows or environmental contamination.

Why Factory-Built Systems Are Ideal for Sunrise Beach, MO

Sunrise Beach presents a unique set of challenges for wastewater management. The community includes lakefront properties, hilly terrain, and a mix of permanent and seasonal residents. These factors make a standardized approach to sewage collection difficult. Factory-built lift stations provide a flexible and scalable solution.

These systems can be custom-designed to meet the specific needs of a site, including considerations for space, flow rate, and environmental conditions. They arrive ready for installation, which minimizes construction disruptions and ensures consistent quality. Furthermore, modern units are designed with corrosion-resistant materials that extend the life of the station and reduce long-term maintenance costs.

Factory-built stations also integrate easily with existing infrastructure, whether for a new residential development or an upgrade to aging municipal systems. For property owners and public works departments, this ease of integration means fewer headaches and a more resilient system overall. Given the varying elevations and the importance of keeping Lake of the Ozarks clean and safe, the efficiency of waterwaste lift stations is critical to the long-term sustainability of the area.

Environmental and Regulatory Considerations

Managing wastewater responsibly involves more than just moving it from one point to another. Lift stations in Sunrise Beach must adhere to strict environmental and public health regulations. These include guidelines from the Missouri Department of Natural Resources and the Environmental Protection Agency, which cover construction, operation, and maintenance practices.

Preventing sewage overflows is a top priority. That’s why modern lift stations include high-level alarms and overflow prevention systems. Many are also designed to prevent odor release and to minimize noise, making them suitable for installation near residential areas without disrupting the local environment.

Additionally, regular maintenance and inspections are necessary to keep the systems running efficiently. Factory-built lift stations make this easier through standardized parts, easy-access components, and remote monitoring features. These attributes help municipalities stay compliant with regulations while also maintaining the safety and cleanliness of local waterways.

Conclusion

In communities like Sunrise Beach, MO, waterwaste lift stations play an essential but often overlooked role in public infrastructure. By moving wastewater efficiently across varying terrain, these systems help maintain hygiene, protect natural resources, and support both residential and commercial development.

Factory-built lift stations provide a reliable and adaptable solution for the region’s wastewater challenges. Their engineered design, ease of installation, and robust features make them a smart investment for both municipalities and private property owners. Whether tucked away beneath a quiet neighborhood or installed alongside a bustling lakeside resort, lift stations are the unsung heroes keeping water flowing safely and efficiently.

Understanding their anatomy, operation, and importance is the first step toward appreciating the complexity and necessity of modern wastewater management. As Sunrise Beach continues to grow and evolve, these systems will remain vital to ensuring a healthy and sustainable future for the entire community.

Need Pumping Equipment Near You?

Categorised in: Factory-Built Lift Stations