Extending the Lifespan of Your Wet Pit Submersible Pump: Essential Maintenance Tips in Osawatomie, KS

Maintaining a wet pit submersible pump is vital for ensuring its long-term performance and efficiency. This type of pump is widely used in places like Osawatomie, KS, where heavy rains and water systems are prevalent. Whether it’s used in residential applications or in industrial settings, a wet pit submersible pump plays a crucial role in managing water levels and preventing flooding. However, like any mechanical device, regular maintenance is key to ensuring its functionality and avoiding costly repairs. In this article, we will explore essential sump pump maintenance tips that will help extend the lifespan of your wet pit submersible pump and keep it running smoothly.

The Importance of Sump Pump Maintenance

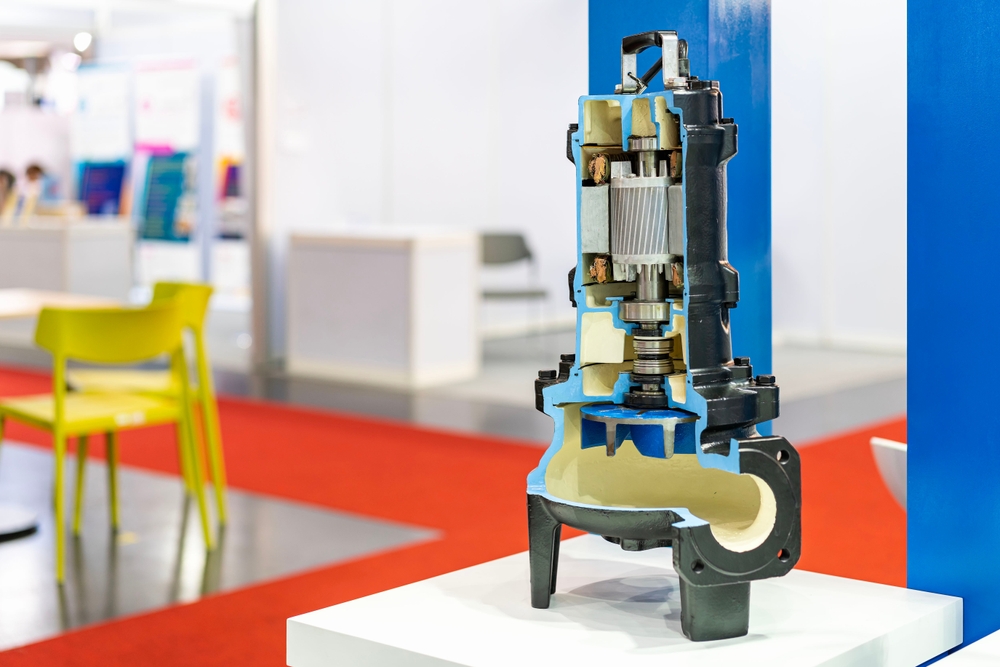

Sump pumps are designed to remove water that accumulates in a sump basin, typically found in basements or crawlspaces. Wet pit submersible pumps are specifically designed to operate while submerged in water, making them ideal for use in areas where water frequently collects. Over time, these pumps are exposed to a variety of factors such as debris, dirt, and mineral buildup, all of which can impact their efficiency and longevity.

Regular maintenance is essential because it ensures that the pump operates as intended, preventing unnecessary wear and tear. A well-maintained pump reduces the risk of failures during critical times, such as during heavy storms or seasonal flooding. By investing in sump pump maintenance tips and taking proactive measures, you can help avoid expensive repairs or replacements while also protecting your property from water damage.

Routine Inspection and Cleaning

One of the most important maintenance tasks for a wet pit submersible pump is routine inspection and cleaning. This involves checking the pump for any visible signs of damage or wear and clearing any debris that may have accumulated. Over time, sediment, leaves, and other debris can get sucked into the pump, leading to clogging or damage. Regularly inspecting your pump ensures that any issues are caught early before they can cause significant damage.

When inspecting the pump, start by checking the power supply. Ensure that the pump is receiving the proper voltage and that all electrical connections are secure. Look for any frayed wires or signs of corrosion. Next, check the intake screen and the discharge pipe. If these areas are clogged with debris, water flow will be restricted, causing the pump to work harder and potentially fail. Cleaning these areas regularly will keep the pump running efficiently.

In addition to cleaning the external components, it’s also important to inspect the internal parts of the pump. Remove any buildup of dirt or minerals that may have accumulated inside the pump’s motor or impeller. Regular cleaning of the motor will prevent it from overheating and reduce the likelihood of failure.

Checking the Float Switch and Backup Systems

The float switch is a critical component of your wet pit submersible pump. It is responsible for detecting the water level and activating the pump when necessary. If the float switch becomes stuck or malfunctioning, the pump may fail to turn on when needed, leading to water accumulation and potential flooding. To ensure the float switch is operating correctly, inspect it regularly for any signs of wear or malfunction.

Test the float switch by raising and lowering it to simulate the changes in water levels. If it does not trigger the pump to start or stop, it may need to be repaired or replaced. Additionally, it’s essential to check any backup systems, such as battery backups or secondary pumps. These systems provide additional protection in case the primary pump fails, especially during power outages or extreme weather conditions. Regular testing of these backup systems ensures that they are ready to operate when necessary.

By incorporating regular checks of the float switch and backup systems into your sump pump maintenance routine, you can reduce the risk of unexpected failures and ensure that your pump is always functioning as expected, even in emergency situations.

Preventing Freeze Damage and Corrosion

In Osawatomie, KS, winters can be harsh, and freezing temperatures pose a significant threat to your wet pit submersible pump. Freeze damage occurs when water inside the pump or discharge pipe freezes, causing it to crack or become clogged. To prevent this, it’s essential to take measures to protect the pump from freezing temperatures.

First, ensure that the discharge pipe is properly insulated, especially in areas where it is exposed to the outside elements. Insulation helps to maintain the temperature of the water inside the pipe, preventing it from freezing. If possible, direct the discharge pipe away from areas where water can accumulate and freeze, such as near the foundation of the home or in low-lying areas.

In addition to protecting the discharge pipe, it’s also important to winterize the pump itself. This can be done by removing the pump from the pit during the coldest months of the year and storing it in a dry, warm location. Before storing the pump, clean it thoroughly and check for any signs of wear or damage. If you choose to leave the pump in the pit, ensure that the sump basin is well-drained and does not contain standing water that could freeze.

Corrosion is another issue that can arise over time, especially in areas with high levels of humidity or exposure to harsh chemicals. To prevent corrosion, inspect the pump’s metal components regularly for signs of rust or damage. If any corrosion is detected, clean it immediately using a mild detergent and a soft brush. In some cases, it may be necessary to apply a rust inhibitor to protect the metal parts from further damage.

Professional Inspections and Repairs

While routine maintenance and cleaning are crucial for keeping your wet pit submersible pump in good working condition, it’s also essential to have professional inspections and repairs done periodically. Professional pump technicians can provide a more thorough inspection, checking for issues that may not be immediately visible to the untrained eye.

During a professional inspection, the technician will test the pump’s performance, check for any internal issues, and ensure that all parts are functioning properly. If any issues are found, the technician can make necessary repairs or recommend replacements before the problem becomes more severe. Regular professional inspections help to identify potential problems early, ensuring that your pump is always ready to perform when needed.

In addition to inspections, it’s important to consider having your pump serviced by a professional if it shows any signs of malfunction, such as unusual noises, irregular operation, or an inability to pump water efficiently. A professional technician will have the knowledge and tools required to address these issues, ensuring that your wet pit submersible pump is functioning at its best.

Conclusion

Extending the lifespan of your wet pit submersible pump requires consistent maintenance and care. By following essential sump pump maintenance tips such as regular inspections, cleaning, checking the float switch and backup systems, preventing freeze damage, and scheduling professional inspections, you can ensure that your pump continues to perform efficiently for years to come. In Osawatomie, KS, where water systems are crucial, taking proactive steps to maintain your wet pit submersible pump will help protect your property from flooding, water damage, and costly repairs. Whether you handle the maintenance yourself or enlist the help of a professional, investing in the care of your sump pump is an investment in the long-term protection of your home or business.

Need Pumping Equipment in Osawatomie, KS?

Categorised in: Wet Pit Submersibles